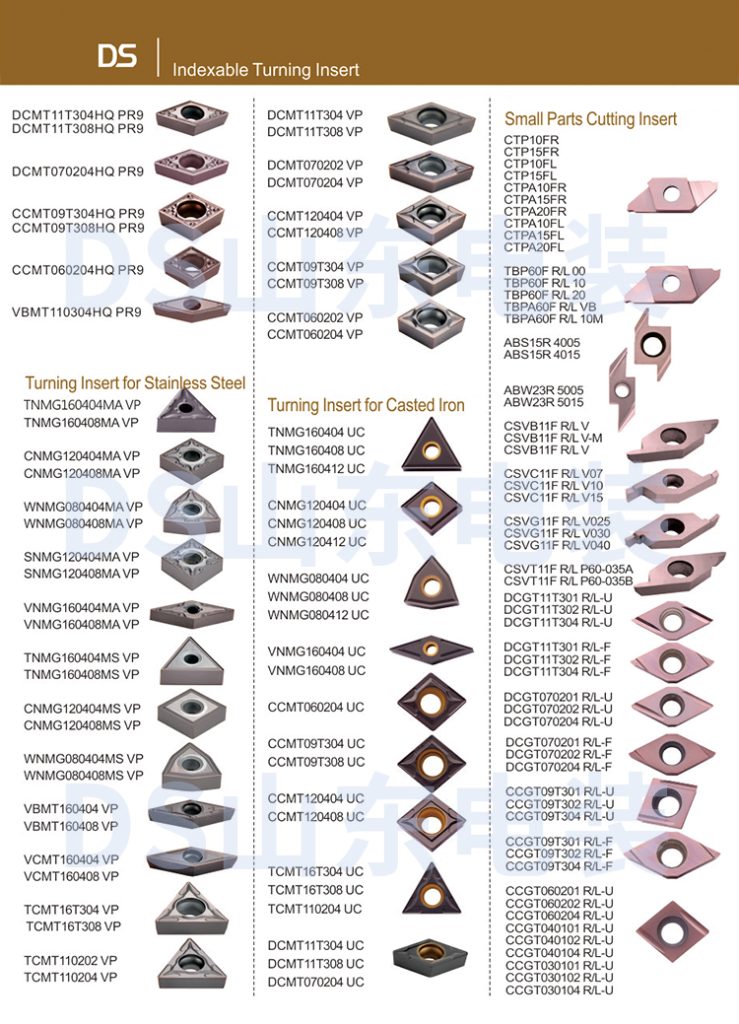

Indexable Inserts: Enhancing Cutting Efficiency and Tool Performance

Indexable inserts are an important component of indexable tools, providing multiple cutting edges that can be easily replaced or repositioned. Compared to welded and integral tools, indexable tools offer significant advantages. In this article, we will delve into the concept of indexable tools, explore their characteristics and highlight their advantages over welded tools.

Basic concepts of indexable tools:

An indexable tool is a tool that uses mechanical clamping to securely clamp a pre-machined polygonal insert with multiple cutting edges to the tool body. When one cutting edge becomes dull during use, the clamping is released, allowing the insert to be indexed or replaced. By positioning the new cutting edge in the working position, the tool can continue to be used after re-clamping.

Features of indexable tools:

Compared to welded and integral tools, indexable tools have two main features:

a) Multiple cutting edges: The insert mounted on the tool body has at least two pre-machined cutting edges available for use. This feature allows efficient use of the tool, as when one cutting edge becomes dull, it can be indexed or replaced while maintaining the same geometrical parameters.

b) Fixed cutting edge position: The position of the cutting edge on the tool body remains constant after indexing of the insert. This stability ensures consistent cutting performance and eliminates the need for readjustment, saving time for tool changes and increasing machine availability.

Advantages of indexable inserts over welded tools:

Indexable inserts offer several distinct advantages over welded tools:

a) Enhanced cutting performance: Indexable inserts provide better cutting performance as a separate functional element. Thanks to the variety of insert materials available, the optimum selection can be made depending on the material being machined, maximising cutting efficiency.

b) Process flexibility: The mechanical clamping of indexable inserts eliminates the limitations of the welding process. This makes it possible to utilise inserts made from different materials, further improving cutting performance and efficiency.

c) Time savings: The fixed spatial position of the cutting edge relative to the tool body eliminates the need for time-consuming adjustments to the tool during insert indexing. This results in a reduction in auxiliary time and an increase in overall productivity.

d) Cost-effectiveness: Indexable tools are economically efficient due to their high cutting efficiency and reduced auxiliary time. The reusability of the tool body keeps steel and manufacturing costs to a minimum. In addition, the specialisation and standardised production of indexable tools drives the entire manufacturing process of cutting tools.

The development of indexable tools has contributed significantly to the advancement of cutting tool technology. These tools have increased cutting efficiency, improved tool performance and contributed to the standardisation and specialisation of cutting tool production. By taking advantage of indexable inserts, manufacturers can achieve higher productivity, cost savings and improved machining quality in their operations.

About Us

We have been engaged in precision manufacturing since 2000, and we are committed to personnel training, product development, technology development and equipment renewal, steadily growing into one of the outstanding companies in China for precision tools.

Address

- E-mail:eva@densotool.com

- Tel: 0539-4687610

- Skype:(+1)2134255500

- WhatsAPP:(+1)2134255500

- Telegram: https://t.me/densotoolsoem

- Address: Taihe Road, Dongcheng Development Zone, Pingyi County, Linyi City, Shandong Province,China