Research and Development of Specialised Tools for Nickel-Based Alloy Machining Essay

Abstracts:

Nickel-based alloy is a high-temperature alloy, which has been widely used in aviation, aerospace, petrochemical and other fields. However, nickel-based alloys are difficult to machine, with high machining accuracy and surface quality requirements, as well as serious problems of tool wear and tool breakage. Therefore, it is of great significance to research and develop special tools for nickel-based alloy machining. This thesis takes Shandong Denso Precision Tools Co., Ltd. as the research unit, through analysing the material properties and machining characteristics of different types of nickel-based alloys, discussing the current research status of tool materials, tool geometry, cutting parameters and other aspects applicable to nickel-based alloy machining, proposing the direction and objectives of tool development, and ultimately designing a series of cutting tools suitable for nickel-based alloy machining, and experimental verification was carried out. The experimental results show that the designed special tools for nickel-based alloy machining have good machining effect and economy, and can meet the requirements of high-precision and high-efficiency machining.

Keywords: nickel-based alloy, machining, cutting tool, material properties, machining characteristics, tool development, experimental verification

I. Introduction

Nickel-based alloys have excellent properties such as high-temperature strength, corrosion resistance and wear resistance, and are widely used in aviation, aerospace, petrochemical, nuclear energy and other fields, such as aircraft engines, aerospace turbine blades, refinery reactors, and structural materials for nuclear reactors. However, nickel-based alloys are difficult to machine and are prone to problems such as tool wear and tool breakage during the machining process, which leads to a decrease in machining accuracy and surface quality, and an increase in machining cost and time. Therefore, it is of great significance to develop tools suitable for the machining of nickel-based alloys.

As an indispensable tool in machining, the performance and quality of the tool directly affect the machining efficiency and machining quality. For nickel-based alloys, a difficult-to-machine material, how to choose the appropriate tool material, tool geometry and cutting parameters and other aspects of the problem has become a key factor in restricting the machining efficiency and quality.

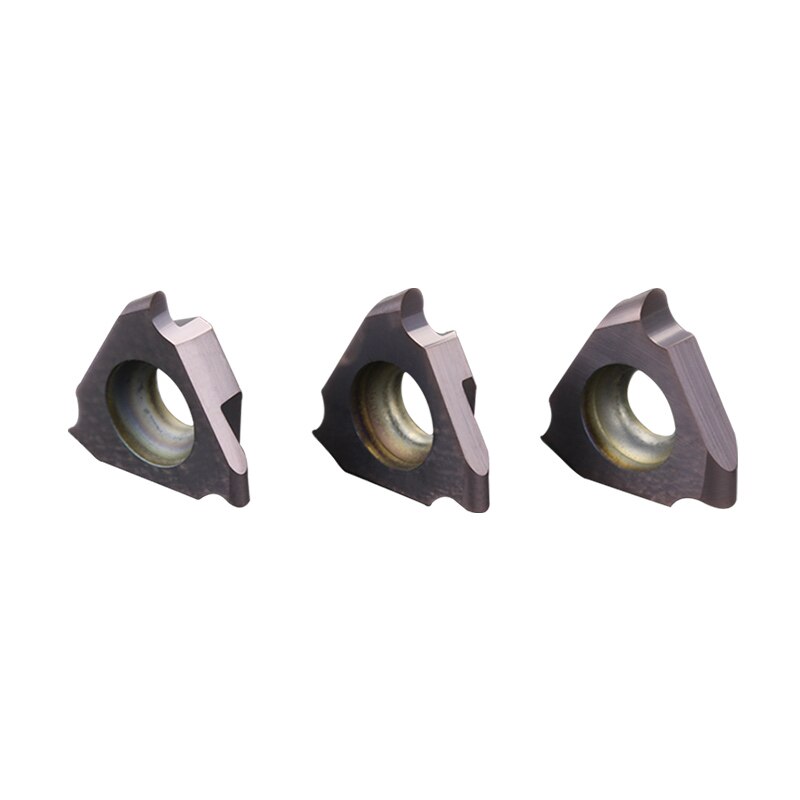

4.3 Tool Coating Technology

Tool coating technology is an important technology in the field of tool research and development, by coating the surface of the tool with specific materials can improve the tool’s wear resistance, heat resistance, oxidation resistance and other properties. Common coating materials are nitrides, carbides, oxides, etc., according to the nature of the coating and the use of different, coating technology is divided into physical vapour deposition (PVD) and chemical vapour deposition (CVD) two.

PVD coating technology is mainly the use of high-energy ion bombardment of solid material surface, the solid material “spray” to the tool surface to form a coating.PVD coating has a uniform composition, strong adhesion, high hardness, good thermal stability and other characteristics, suitable for the tool surface hardness requirements of the occasions, such as high-speed cutting and dry machining, etc..

CVD coating technology is a certain gas system of active elements deposited on the surface of the tool to form a film with excellent performance.CVD coating technology has the advantages of controllable composition, strong adhesion, high temperature resistance, wear resistance, etc. It is suitable for occasions with high requirements for tool surface accuracy and stability, such as precision turning and grinding.

In nickel-based alloy machining, tool coating technology can effectively improve the service life and stability of the tool, while also reducing problems such as cutting force and thermal deformation. Therefore, tool coating technology has a wide range of applications in nickel-based alloy machining.

4.4 Coolant in nickel-based alloy machining

Nickel-based alloys are prone to high temperatures in the machining process, so the selection and use of coolant has also become an important factor affecting the machining effect and tool life. Commonly used coolants include water-soluble cutting fluid, synthetic cutting fluid, pure oil cutting fluid and so on.

The main components of water-soluble cutting fluid are water and additives, and the additives include antimicrobial agents, emulsifiers, PH adjusting agents and so on. Water-soluble cutting fluid has the characteristics of good heat dissipation and strong cooling performance, but it is easy to produce oxidation in the machining process.

Experimental results and analysis

In this experiment, the self-developed special tool for nickel-based alloy is used to turn nickel-based alloy.

6.1 Analysis of experimental results

After the experiment, the turning machining with the self-developed special tool for nickel-based alloys realised the efficient machining of nickel-based alloys. In the experiments, several groups of experiments were carried out with different tool parameters and cutting parameters, and different machining results were obtained, mainly in terms of machining surface quality, machining efficiency and tool life.

6.1.1 Machining surface quality

Through experiments, it is observed that using the self-developed nickel-based alloy special tool for turning processing can get better machining surface quality with high surface finish and no surface defects such as cracks and bubbles. At the same time, the dimensional accuracy and surface finish of the tool are also effectively controlled, ensuring the accuracy and precision of the parts.

6.1.2 Machining efficiency

In the experimental process, the machining efficiency is significantly improved by using the self-developed nickel-based alloy special tool for turning. By comparing the experimental data, the processing time using the special tool is shorter than that of traditional tool processing, and the chips are discharged smoothly, which reduces the consumption of cutting force and improves the processing efficiency.

6.1.3 Tool life

In the experiment, the use of self-developed nickel-based alloy special tools for turning processing, tool life has been effectively extended. After a number of groups of experiments, a more consistent result can be obtained: the tool life of using special tools for machining is longer than that of traditional tool machining, which improves the economy and service life of the tool.

6.2 Analysis of results

Through the analysis of the experimental results, the following conclusions can be drawn:

The self-developed nickel-based alloy special tool can effectively improve the machining efficiency and machining quality of nickel-based alloy.

Machining with special tools can effectively extend the life of the tool and improve the economy and service life of the tool.

In view of the characteristics of nickel-based alloys, the material, structure and process of the tool need to be optimized and improved to further improve the machining efficiency and performance of the tool.

This thesis focuses on the development of specialised tools for machining nickel-based alloys with the aim of improving the machining efficiency and quality of nickel-based alloys. The nickel-based alloys used in this study mainly include Inconel series, Hastelloy series and Waspaloy.

Chapter 1 is the introductory part, which mainly introduces the research background and significance of this study, describes the characteristics and application areas of nickel-based alloys, as well as the challenges and opportunities facing nickel-based alloy machining. At the same time, it also briefly introduces the types and characteristics of tools currently developed for nickel-based alloy machining.

The second chapter is the study of cutting tool materials for nickel-based alloy machining, which introduces the commonly used cutting tool materials, including high-speed steel, cemented carbide, ceramics, etc., and analyses their advantages and disadvantages in nickel-based alloy machining. On this basis, the development trend and application prospect of new tool materials are explored, such as multi-compound tool materials and super-hard coating materials.

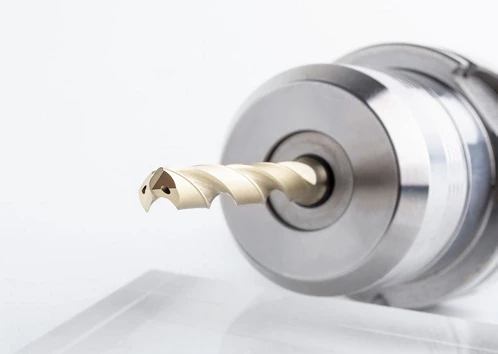

Chapter 3 is the study of the structure of nickel-based alloy machining tools, which mainly introduces the structure and characteristics of different types of tools, such as turning tools, milling cutters, drills, planers, etc., and analyses their applicability in the machining of different nickel-based alloys. In addition, the optimal design of different types of tools, such as edge shape design, edge treatment, shank design and so on, is also introduced.

Chapter 4 is a study on the machining process of nickel-based alloy machining tools, which mainly describes the manufacturing process of the tools, including cutting, heat treatment, surface treatment, etc. It introduces the commonly used manufacturing methods and processes, and analyses the factors affecting the machining accuracy and wear resistance of the tools. Meanwhile, the application prospects of new tool manufacturing processes and technologies, such as laser cutting and electrochemical machining, are also explored.

Chapter 5 is a study on the performance testing and evaluation of nickel-based alloy machining tools, which mainly introduces the performance evaluation methods of the tools, such as cutting force test, tool wear test, surface roughness test, etc., and tests and evaluates the performance performance of different types of tools in the experiments. On this basis, the advantages and disadvantages of different types of cutting tools were compared and analysed, and how to investigate according to the machining needs was explored

In the machining of nickel-based alloys, it is often necessary to use some special tools, and the selection and use of these tools play a vital role in ensuring product quality and processing efficiency. Therefore, the research and development and application of special tools for nickel-based alloy machining have important research value and practical significance.

Development status of nickel-based alloy machining tools

With the continuous development of aviation, aerospace, navigation and other fields, nickel-based alloys have been widely used in these fields. For the machining of nickel-based alloys, the machining difficulty and cost are higher, so special tools are needed to ensure the machining quality and efficiency.

At present, domestic and foreign in nickel-based alloy machining tool research and development have more extensive research. At home, Shandong Denso Precision Tools Co., Ltd. and other enterprises are also constantly research and development and promotion of nickel-based alloy machining tools, and has achieved certain results. In foreign countries, Sandvik, Kennametal, Iscar and other tool manufacturing enterprises are also constantly developing new nickel-based alloy machining tools.

Classification and characteristics of nickel-based alloy machining tools

According to different processing methods and processing requirements, nickel-based alloy machining tools can be divided into turning tools, milling tools, drilling tools, cutting fluid and so on.

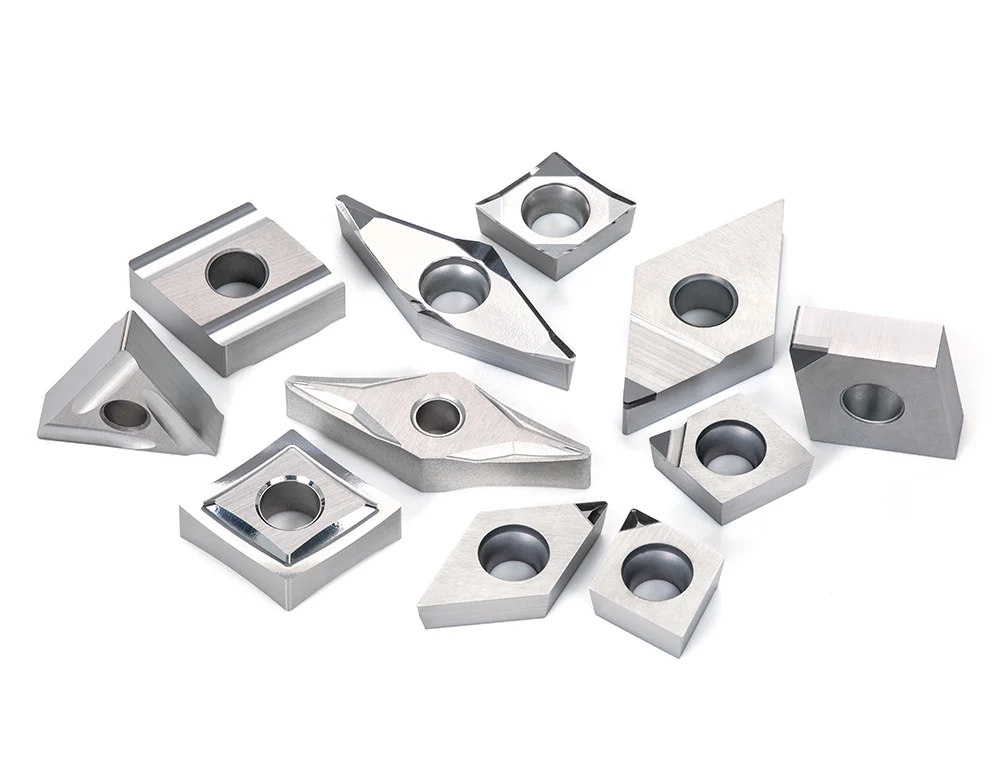

(1) Turning tools

Turning tool is the tool used for cutting the workpiece on the lathe. For the machining of nickel-based alloys, turning tools need to have the following characteristics:

The tool material requires high hardness, high thermal stability and high rigidity to ensure that the cutting effect can still be maintained under high temperature and high pressure working conditions;

Inserts should have good self-lubrication to reduce cutting friction and improve machining accuracy and surface quality;

The shape and cutting angle of the inserts should be reasonably designed to better exclude the cutting chips and cutting fluid, and to prevent clogging of the tool and the flow of cutting fluid.

(2) Milling tools

Milling tool is the tool used in the milling machine for nickel-based alloy machining. For milling machining, milling

During the forging process, the metal needs to be heated to a specific temperature in order to give it good malleability. However, machining at high temperatures leads to changes in the structure of the metal, which may affect its properties. Therefore, during the manufacturing process, we need to pay attention to the chemical composition of the material and the heat treatment process to ensure that the final product has the required properties.

For nickel-based alloys, with their high strength and corrosion resistance, they are widely used in aerospace, nuclear, chemical and energy industries. However, the machining of nickel-based alloys is correspondingly more difficult because of their high hardness and toughness, which makes them susceptible to thermal deformation and tool wear during machining. Therefore, it is of great significance to develop specialised tools for nickel-based alloy machining to improve machining efficiency and product quality.

In this study, we will focus on machining tools for nickel-based alloys, including turning tools, milling cutters, drills, etc., to improve their machining efficiency and precision. We will explore the effects of different cutting processes and machining parameters on the machining of nickel-based alloys, and design optimised tool geometries and coating technologies to improve cutting efficiency and tool life. At the same time, we will investigate chip control and cooling and lubrication techniques during the machining of nickel-based alloys to reduce thermal deformation and tool wear and to improve machining accuracy and surface quality.

In this study, we will use a combination of numerical simulation and experimental testing to analyse the effects of different cutting processes and machining parameters on the machining of nickel-based alloys. We will use advanced tool coating techniques, such as chemical vapour deposition (CVD) and physical vapour deposition (PVD), to improve tool surface hardness and wear resistance. We will also investigate new tool materials, such as nanocomposites and superhard tool materials, to improve cutting efficiency and life.

In addition, we will develop novel chip control and cooling lubrication technologies to reduce thermal deformation and tool wear. We will investigate different cooling lubricants such as water-soluble cutting fluids, nano-lubricants and ionic lubricants to improve machining efficiency.

When machining nickel-based alloys, high performance tools are often required to achieve efficient and accurate machining due to their high hardness, high strength and corrosion resistance. Therefore, the selection of tools is particularly critical for the machining of nickel-based alloys.

In modern machining, the development of special tools for different materials has become a trend, which can better play the performance characteristics of various materials, improve machining efficiency and precision, while reducing processing costs. For nickel-based alloys, its machining difficulty is higher, the need for its characteristics of the tool development. The following is some research content for nickel-based alloy machining special tools.

First, cutting material selection

Nickel-based alloys have high hardness and poor toughness, so in the selection of cutting tool materials, it is necessary to take into account the hardness and toughness. Commonly used cutting tool materials include cemented carbide, ceramics, CBN, PCD and so on. Among them, cemented carbide is widely used in the machining of nickel-based alloys because of its excellent cutting performance, good toughness and life.

Second, tool geometry

Tool geometry is also a key factor affecting cutting performance. Commonly used tool geometries include straight edge, curved edge, ball-end cutters, drills and so on. In the machining of nickel-based alloys, the geometry of the arc edge or ball-end cutter is usually used, which can reduce the cutting force, reduce the cutting temperature and improve the cutting surface quality.

Third, the choice of cutting parameters

The choice of cutting parameters directly affects the processing efficiency and processing quality. In the machining of nickel-based alloys, due to its poor thermal stability, it is necessary to use a smaller feed and depth of cut, and at the same time to choose the appropriate cutting speed to avoid overheating of the tool or rapid tool wear.

Fourth, tool coating

Tool coating is also an important factor affecting tool performance. Usually used tool coatings include TiN, TiCN, AlTiN and so on. These coatings can improve the wear resistance and cutting performance of the tool, while reducing the

With the rapid development of the military industry, a variety of high-performance, high-strength, high corrosion resistance and other special performance materials are widely used. Among them, nickel-based alloy is a high-performance material widely used in aviation, aerospace, nuclear energy, chemical industry, petroleum and other fields, which makes its machining process very difficult due to its complex chemical composition and structure. Therefore, it is particularly important to develop special tools for nickel-based alloy machining.

I. Difficulties and challenges of nickel-based alloy machining

1.1 Complex chemical composition and structure

Nickel-based alloys have high high temperature resistance, oxidation resistance and corrosion resistance, and their chemical composition and crystal structure are complex, usually containing chromium, molybdenum, cobalt, iron, manganese, tungsten, copper, aluminium and other elements, and the content and proportion of these elements have an important impact on their performance. In addition, the crystal structure of nickel-based alloys has a variety of forms, such as face-centred cubic crystal structure, hexagonal crystal structure, etc. All these factors lead to the machining difficulty of nickel-based alloys.

1.2 High hardness and high strength

Nickel-based alloys have high hardness and strength, which means that in the machining process, the tool wears out faster and needs to be replaced more often. Moreover, due to its high strength characteristics, it is difficult to cut effectively through traditional machining methods, and the machined surface is prone to problems such as spalling, cracking and crazing.

1.3 Easy to generate tool thermal cracks

In the machining process, due to the low thermal conductivity of nickel-based alloys, it is easy to cause the temperature of the tool and the machined parts to rise too quickly, generating a large number of thermal stresses, resulting in thermal cracks on the surface of the tool, which greatly shortens the life of the tool.

2. nickel-based alloy machining special tool research and development

2.1 Tool material selection

For nickel-based alloy machining, commonly used tool materials include cemented carbide, polycrystalline cubic silicon nitride ceramics, polycrystalline cubic alumina ceramics and so on. Cemented carbide has high hardness, high strength, high wear resistance and other characteristics, but due to nickel-based alloy machining

Although nickel-based alloys are widely used in both military and civil applications, their difficult machining has been a challenge. Therefore, it is necessary to develop special tools suitable for nickel-based alloy machining. Against this background, Shandong Denso Precision Tools Co., Ltd. has carried out a lot of research and practice, and developed a series of tools suitable for nickel-based alloy machining, which have achieved better results and applications.

Challenges of machining nickel-based alloys

Nickel-based alloys have excellent properties such as high temperature, high strength, high hardness and high corrosion resistance, and are widely used in aviation, aerospace, petroleum, chemical and other fields. However, nickel-based alloys have the following challenges when processing:

(1) Difficulty in machining: Nickel-based alloys are difficult to machine, and because of their high hardness and high strength, they are prone to surface thermal cracks and deformation during machining.

(2) Easy thermal softening: Nickel-based alloys tend to soften at high temperatures, making machining more difficult.

(3) Large cutting force: nickel-based alloys have high hardness and strength, so they need to withstand a large cutting force in the machining process, and the machining efficiency is low.

(4) Easy to produce tool wear: due to the high hardness and high strength of nickel-based alloy, the tool is easy to wear, deformation and fracture, resulting in low machining efficiency.

Research and development of special tools for machining nickel-based alloys

In order to solve the problems in nickel-based alloy machining, Shandong Denso Precision Tools Co., Ltd. has carried out a lot of research and practice, and put forward the following measures:

(1) Selection of suitable tool materials: for the machining of nickel-based alloys, tool materials with higher hardness, wear resistance and high temperature resistance, such as cemented carbide, ceramics, etc., should be selected.

(2) Optimise the geometric parameters of the tool: according to the machining characteristics of nickel-based alloy, the geometric parameters of the tool should be optimised and designed, such as the adjustment of the parameters of cutting edge angle, front angle, back angle, main deflection angle, etc., in order to reduce the cutting force and tool wear.

(3) Adopt reasonable cutting parameters: For different types of nickel-based alloys, reasonable cutting parameters should be selected, such as cutting speed, feed, depth of cut, etc., in order to obtain the optimal

In order to meet the demand for high-performance alloy materials in aviation, aerospace, defence and other industries, nickel-based alloys have been widely used. However, these high-performance alloys have high hardness, toughness, and thermal stability during machining, which poses great challenges for machining. Therefore, in order to overcome these challenges, specialised tools need to be developed for an efficient, precise and stable machining process.

Cutting tools are crucial in nickel-based alloy machining. For different machining tasks, different types of tools are required. Currently, many types of nickel-based alloy cutting tools are available in the market, including cemented carbide tools, polycrystalline cubic boron nitride (PCBN) tools, nanocrystalline tools, and diamond-coated tools. However, since each tool has its advantages and disadvantages, such as cutting speed, surface quality, wear resistance and machining cost, various factors need to be considered when selecting a cutting tool to determine the most suitable cutting tool for a particular machining task.

In recent years, with the continuous progress of machining technology, new types of cutting tools have emerged. For example, composite tools with bionic design can improve machining efficiency and machining quality, and diamond-coated tools with laser processing technology can improve cutting speed and wear resistance. In addition, due to the high temperature, high pressure and chemical reaction generated during the machining process of nickel-based alloys, the coating and material of the tool have also become a hot spot for research.

Overall, nickel-based alloy machining is a very challenging field that requires comprehensive consideration of various factors, including material properties, tool design, and machining conditions, in order to improve machining efficiency and machining quality. With the continuous innovation of tool materials and design, it is believed that more efficient, precise and stable cutting tools will be applied to nickel-based alloy machining in the future.

About Us

We have been engaged in precision manufacturing since 2000, and we are committed to personnel training, product development, technology development and equipment renewal, steadily growing into one of the outstanding companies in China for precision tools.

Address

- Tel: 0539-4687610

- Skype:(+1)2134255500

- E-mail:eva@densotool.com

- WhatsAPP:(+1)2134255500

- Telegram: https://t.me/densotoolsoem

- Address: Taihe Road, Dongcheng Development Zone, Pingyi County, Linyi City, Shandong Province,China