Tooling for High Temperature Alloys Research Paper

High-temperature alloys are metal alloy materials that still have good mechanical properties and corrosion resistance under high-temperature environments. Because it has a wide range of applications in aerospace, energy, automotive and other fields, so the machining technology of high temperature alloys has also attracted much attention. For the machining of high temperature alloys, you need to choose the right tool to achieve higher machining efficiency and longer tool life.

This article will introduce Shandong Denso Precision Tools Co., Ltd. research and development for high-temperature alloy cutting tools, and high-temperature alloy machining-related issues to discuss.

A high-temperature alloy processing difficulties

1. High hardness: the hardness of high temperature alloy materials is often very high, usually up to 50-60 HRC, or even higher. This makes machining difficult and can easily lead to tool wear and fracture.

2. High-temperature thermal deformation: in a high-temperature environment, high-temperature alloy materials are prone to thermal deformation, resulting in reduced machining accuracy and poor surface quality.

3. Difficult chip removal: due to the poor toughness of high-temperature alloy materials, it is easy to form burrs, scratches and other surface defects in the machining process, affecting the machining quality.

Second, the choice of high-temperature alloy tools

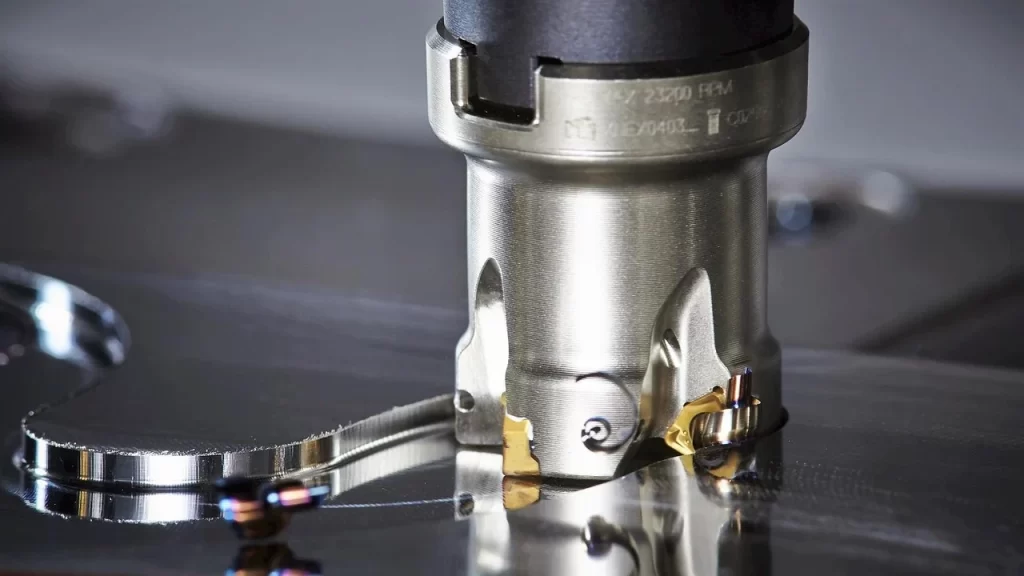

1. High-temperature alloy milling cutter: High-temperature alloy milling cutter usually adopts the design of smaller cutting edge diameter and longer shank to improve rigidity and reduce vibration. At the same time, the use of high hardness tip material and high precision tool geometry to improve machining accuracy and tool life.

2. High-temperature alloy turning tools: High-temperature alloy turning tools usually use inserts made of super-hard alloy materials to improve hardness and wear resistance. At the same time, fine insert machining technology and tool geometry are used to reduce chip accumulation and improve machining quality.

3. High-temperature alloy special tools: due to the special nature of high-temperature alloys, the need for special R & D for its processing of tools, such as high-temperature alloy inserts, high-temperature alloy turning tools, high-temperature alloy milling cutters and so on. These tools usually use advanced materials and manufacturing processes to meet the special requirements of high-temperature alloy machining.

Third, the development of high-temperature alloy tools

For the research and development of high temperature alloy tools, the following factors need to be considered:

1. Selection of tool materials: high temperature alloy materials have high hardness, so it is necessary to choose materials with high hardness and wear resistance. Commonly used materials include tungsten carbide, PCD, CBN, ceramics and so on. At the same time, it is also necessary to consider the rigidity, toughness and thermal resistance of the tool.

2. Optimisation of tool geometry: for the machining of high temperature alloys, the design of tool geometry is very important. According to different machining methods and material properties, it is necessary to design a suitable tool shape, cutting angle, edge shape and so on. At the same time, it is also necessary to consider the coating of the tool, cutting edge machining accuracy and other factors.

3. Optimisation of machining parameters: for the machining of high temperature alloys, it is necessary to choose suitable machining parameters, including cutting speed, feed, depth of cut, etc.. It needs to be optimised and adjusted according to different tool materials and machining methods to achieve better machining results and tool life.

IV. Summary

The machining of high temperature alloy is difficult, and it is necessary to choose the right tool and optimise the machining parameters to achieve better machining results and tool life. Shandong Denso Precision Tools Co., Ltd. developed high-temperature alloy tools, the use of advanced materials and manufacturing processes, with excellent rigidity, toughness and heat resistance, can meet the requirements of high-temperature alloy machining. In the future research and development work, it is also necessary to further explore the mechanism of high temperature alloy machining and optimisation of tool design to meet the changing market demand.

In addition, the research and development of high-temperature alloy tools also need to consider the factors of environmental protection and energy saving. With the continuous development of the global economy, the demand for energy is also growing, and the problems of environmental protection and energy saving are becoming more and more prominent. In the process of high temperature alloy machining, if the use of high energy consumption and pollution of the machining process and materials, will cause irreversible impact on the environment. Therefore, in the research and development of high temperature alloy tools, it is necessary to consider the renewability of materials, energy consumption in the production process, waste disposal and other factors, in order to minimise environmental pollution and waste of resources.

At the same time, the research and development of high-temperature alloy tools also need to focus on independent innovation and intellectual property protection. Innovation is an important driving force for the development of enterprises, and only through continuous technological innovation and product innovation can we take advantage of the competition in the market. Therefore, in the R & D process of high-temperature alloy tools, the need to strengthen the protection of intellectual property rights, to avoid infringement and abuse of intellectual property rights, and to improve the ability and competitiveness of the enterprise’s independent innovation.

Finally, it should be pointed out that the research and development of high-temperature alloy tools is a complex and long-term work. In addition to the above factors, it is also necessary to consider market demand, industrial policy and other factors. In the future R & D process, it is necessary to strengthen communication with users and industry-related parties, in-depth understanding of market demand and trends, and constantly improve and optimise the tool design and manufacturing process to meet the changing needs of customers and the competitive requirements of the market.

To sum up, the research and development of high temperature alloy tools is a challenging and forward-looking work. Shandong Denso Precision Tools Co., Ltd. actively explores and innovates in the R&D of high temperature alloy tools, continuously introduces advanced technologies and materials, strengthens independent innovation and intellectual property rights protection, and is committed to providing customers with better quality tool products and services. In the future development, Shandong Denso Precision Tools Co., Ltd. will continue to strengthen communication and cooperation with users and industry-related parties, and constantly improve and optimise the product design and manufacturing process, to provide customers with higher quality high temperature alloy tool products and solutions.

For the research and development and production of high-temperature alloy tools, there are still many problems that need to continue to explore and solve. For example, the application fields of high-temperature alloys are becoming more and more extensive, and the demand is also growing, which puts forward higher requirements on the performance, precision and life of high-temperature alloy tools, so how to further improve the comprehensive performance of high-temperature alloy tools is also an urgent problem to be solved. In addition, in the processing of high-temperature alloys, it is also necessary to design and produce different types of high-temperature alloy tools for different machining processes, machining parameters and machining materials and other factors, in order to meet different processing needs. Therefore, the future direction of R & D and production should be more refined, personalised and intelligent high-temperature alloy tools to meet a variety of complex high-temperature alloy machining needs, while improving machining efficiency and quality, and make greater contributions to the application and promotion of high-temperature alloy materials.

About Us

We have been engaged in precision manufacturing since 2000, and we are committed to personnel training, product development, technology development and equipment renewal, steadily growing into one of the outstanding companies in China for precision tools.

Address

- Tel: 0539-4687610

- Skype:(+1)2134255500

- E-mail:eva@densotool.com

- WhatsAPP:(+1)2134255500

- Telegram: https://t.me/densotoolsoem

- Address: Taihe Road, Dongcheng Development Zone, Pingyi County, Linyi City, Shandong Province,China